Electronic enclosures, also known as electronic cabinets or electronic enclosure boxes, are boxes that house electrical systems and wiring, like conduits, switches, audio equipment, computer servers and general connections, meant to protect them from damage, contaminants, and interference. They protect their contents from pollutants, moisture, electromagnetic interference and the like. Read More…

At Hubbell Wiegmann, we specialize in designing and manufacturing high-quality electronic enclosures that protect and support a wide range of industrial and commercial systems. We bring decades of engineering expertise to every product we create, ensuring that our enclosures meet rigorous performance standards while adapting to the evolving needs of our customers.

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

At Ometek Inc., we specialize in designing and manufacturing high-quality industrial electronic enclosures for a wide range of applications. Our team of skilled engineers and technicians has years of experience in the industry, and we are committed to delivering the most reliable and durable enclosures to our customers.

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

At Bison ProFab, we provide custom fabrication to perfectly suit your needs. Custom solutions are ideal for a multitude of industries, and our staff can anticipate the needs of our customers. Our team puts a focus on the important qualities, and we tailor these products for durability and longevity. Contact us today to learn more!

More Electronic Enclosure Manufacturers

Applications of Electronic Enclosures

Electronic enclosures are fundamental components in modern electronics, providing reliable protection and housing for electronic devices across a wide spectrum of industries and use cases. Their primary role is to safeguard sensitive circuitry, printed circuit boards (PCBs), and electrical components from environmental hazards, mechanical damage, and unauthorized access. Robust enclosure design is crucial for ensuring optimal performance, regulatory compliance, and long-term reliability.

In industrial automation and manufacturing environments, rugged metal enclosures—including stainless steel and aluminum—protect programmable logic controllers (PLCs), motor drives, industrial control panels, and instrumentation from dust, moisture, oil, chemicals, and mechanical impacts. These industrial electronic enclosures are often specified with NEMA or IP ratings to ensure compatibility with harsh surroundings and to support the operational integrity of critical machinery and process control systems.

For consumer electronics, plastic enclosures deliver both functional protection and visual appeal for devices such as smartphones, tablets, wearable technology, gaming consoles, and smart home controllers. Aesthetic considerations, ergonomic grip, and heat dissipation are key factors in enclosure selection for these applications.

The medical device industry relies on high-quality, precision-engineered enclosures to isolate diagnostic, monitoring, and therapeutic equipment from contaminants and electromagnetic interference (EMI). Medical-grade enclosures must meet stringent regulatory standards (such as ISO 13485) to ensure patient safety, sterility, and ease of sanitization. Typical applications include portable ECG monitors, infusion pumps, imaging systems, and laboratory analyzers.

Within the automotive sector, electronic enclosures are used to shield engine control units (ECUs), battery management systems (BMS), infotainment modules, and advanced driver-assistance systems (ADAS) from heat, vibration, dust, and road debris. These enclosures are engineered with shock absorbers, gaskets, and EMI shielding to maintain system performance in dynamic vehicular environments.

In telecommunications, reliable outdoor enclosures protect network infrastructure—such as routers, switches, fiber optic junctions, and base stations—from weather extremes, UV exposure, and vandalism. These NEMA-rated enclosures are essential for supporting uninterrupted data transmission in both urban and remote locations.

Emerging renewable energy systems and IoT (Internet of Things) deployments also heavily depend on weatherproof electronic enclosures. In solar panel installations, wind turbines, and remote environmental monitoring stations, robust enclosures shield sensitive electronics from rain, snow, salt spray, temperature fluctuations, and wildlife interference.

Have a specific application in mind? Explore the best electronic enclosure solutions for:

- Industrial automation and process control

- Consumer electronics and wearable devices

- Medical devices and healthcare technology

- Telecommunications and networking hardware

- Automotive and transportation electronics

- Renewable energy systems and outdoor IoT sensors

Looking for an enclosure that matches your project’s unique requirements? Browse top electronic enclosure manufacturers or contact an expert to discuss custom solutions.

History of Electronic Enclosures

The evolution of electronic enclosures mirrors the rapid advancement of electrical technology. Originally, enclosures were conceived out of necessity—to prevent accidental contact with live electrical components exposed through basic cutouts and switches. Early designs incorporated simple wooden boxes to encase copper bars and switches, offering a rudimentary barrier between operators and electrical hazards. This approach extended to switchboards used in telecommunication from the late 19th century through the mid-20th century.

As electrical systems proliferated in homes and businesses during the 1920s and 1930s, the limitations of wooden enclosures became apparent. Issues such as loose fittings, overheating, and fire risks prompted a shift toward flame-retardant metals like steel. The increasing complexity of electrical infrastructure demanded more robust, thermally stable, and safer materials.

Today’s modern electronic enclosures are manufactured using advanced materials and processes, including die-cast aluminum, injection-molded polycarbonate, fiberglass composites, and stainless steel. The development of industry standards—such as NEMA and IP ratings—has further refined enclosure design, ensuring protection against environmental threats, mechanical abuse, and electromagnetic interference. This ongoing innovation supports the proliferation of electronics in ever-more demanding environments, from industrial automation to medical diagnostics and beyond.

How Electronic Enclosures Work

Electronic enclosures are engineered to establish a controlled and protective environment for electronic assemblies, ensuring uninterrupted performance and safety. Their primary functions include:

- Environmental Protection: Enclosures create a physical barrier against dust, dirt, water, chemicals, and other contaminants that could degrade electrical performance or cause malfunctions.

- Mechanical Defense: Rigid structures absorb shocks, impacts, and vibrations, preventing physical damage to internal components.

- Thermal Management: Integrated features—such as vents, fans, heat sinks, or phase-change materials—regulate temperature by dissipating excess heat generated during device operation. This is especially critical for power electronics and high-density PCB designs.

- EMI/RFI Shielding: Metallic or conductive coatings block electromagnetic and radio frequency interference, which is vital for maintaining signal integrity and ensuring compliance with FCC and CE regulations.

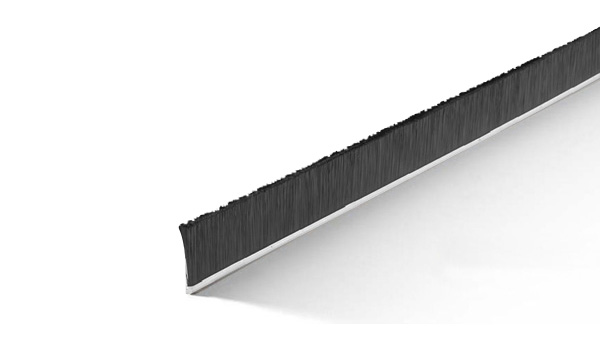

- Ingress Protection: Gaskets, o-rings, and sealing compounds form tight seals at cable entry points, doors, and access panels. These features help enclosures achieve specific ingress protection (IP) or NEMA ratings.

- Safety and Security: Lockable doors, tamper-evident seals, and security screws deter unauthorized access and protect intellectual property.

For more details on how enclosure features can address your specific application challenges—such as EMI prevention, waterproofing, or heat dissipation—see our comprehensive manufacturer directory or explore enclosure customization options.

Types of Electronic Enclosures

Choosing the right enclosure type is vital for matching environmental conditions, regulatory requirements, and functional needs. Below are the most common types, each optimized for specific applications:

- NEMA Enclosures: Rated by the National Electrical Manufacturers Association, these enclosures are designed for both indoor and outdoor use. Their tightly sealed construction prevents ingress of dust, oil, and water, making them ideal for harsh industrial and outdoor applications. NEMA ratings (such as Type 4X for corrosion resistance and Type 12 for dust-proofing) help users select the best enclosure for their environment.

- Computer Enclosures: Built from steel or aluminum, these enclosures are engineered to protect servers, desktop computers, and networking equipment from EMI, dust, and accidental impacts. They often include cooling fans, cable management features, and locking panels for physical security.

- Mounted Enclosures: Designed for wall or surface mounting with fasteners or self-tapping screws, these enclosures are ideal for wireless access points, security systems, and industrial controllers in warehouses and commercial buildings.

- Rack Mount Enclosures: Featuring standardized frames with mounting slots or rails, rack mount enclosures house servers, telecommunications hardware, and AV equipment in data centers and broadcast studios. They are typically made from reinforced aluminum or steel and may include lockable doors, removable panels, and ventilation.

- Fiberglass Enclosures: Constructed from glass-reinforced polyester, these enclosures deliver excellent electrical insulation, corrosion resistance, and impact durability. They are preferred for outdoor, marine, or chemical processing applications where exposure to moisture or corrosive agents is likely.

- ABS Enclosures: Made from acrylonitrile butadiene styrene, ABS enclosures are lightweight, shock-resistant, and cost-effective. They are commonly used for portable instruments, handheld devices, and small-scale consumer electronics.

- Polycarbonate Enclosures: Known for their toughness and clarity, polycarbonate enclosures excel in cold environments and are highly moldable for intricate shapes. They are also UV-resistant, making them suitable for outdoor sensor housings and solar power electronics.

- Stainless Steel Enclosures: These corrosion-resistant enclosures are ideal for food processing, pharmaceutical, and high-temperature environments. Their thermal conductivity helps dissipate heat from enclosed electronics, preventing component failure.

- Aluminum Enclosures: Lightweight yet strong, aluminum enclosures are used for applications requiring efficient heat dissipation and electrical conductivity, such as amplifier housings and industrial control modules. They are produced via extrusion or die-casting for tailored shapes and enhanced durability.

Not sure which type best fits your requirements? Ask yourself:

- Is my application indoor or outdoor?

- What level of water, dust, or chemical protection is needed?

- Do I need EMI/RFI shielding for electronic signals?

- Is thermal management a concern due to power dissipation?

- What are the mounting and accessibility requirements?

For expert advice, contact leading enclosure suppliers or request a quote for custom solutions.

Designing Electronic Enclosures

The process of designing electronic enclosures involves integrating mechanical, electrical, and aesthetic requirements into a functional housing. Manufacturers leverage advanced CAD software, rapid prototyping, and simulation tools to optimize enclosure performance and manufacturability.

Key considerations in enclosure design include:

- Material Selection: Choices range from metals (aluminum, stainless steel, galvanized steel) to engineered plastics (polycarbonate, ABS, fiberglass, Kevlar). Each material provides unique benefits in terms of strength, thermal conductivity, corrosion resistance, and weight.

- Manufacturing Processes: Techniques such as injection molding, die casting, extrusion, stamping, and CNC machining are chosen based on enclosure complexity, production volume, and material type.

- Thermal Analysis: Simulation of heat dissipation, airflow, and component placement helps prevent overheating and extends device lifespan.

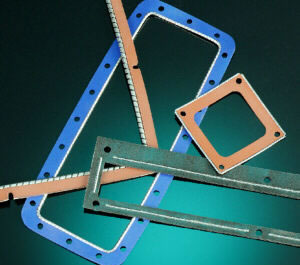

- EMI/RFI Shielding: Incorporation of conductive coatings, grounding provisions, and gasketed seams protects sensitive electronics from signal interference.

- Ingress Protection: Design features like overmolded gaskets, double-wall construction, and waterproof seals enable enclosures to meet desired IP or NEMA ratings.

- Mounting and Access: Provisions for wall, DIN rail, or rack mounting, as well as access points for connectors, switches, and displays, are integrated to simplify installation and maintenance.

- Ergonomics and Aesthetics: For consumer-facing products, enclosure design also considers user interaction, branding, and visual appeal.

Looking to accelerate your enclosure design process? Ask our experts about:

- Rapid prototyping and 3D-printed enclosure samples

- Designing for manufacturability and cost-efficiency

- Best practices for thermal and EMI management

Check out our manufacturer listings for design support and engineering services.

Customizing Electronic Enclosures

Custom electronic enclosures are engineered to address unique application challenges, industry standards, and branding requirements. Leading enclosure manufacturers offer extensive customization options, including:

- Impact and Shock Protection: Reinforced structures, rubberized bumpers, and internal shock mounts protect delicate electronics from drops, vibration, and mechanical abuse. This is essential for handheld devices, portable test equipment, and ruggedized industrial controls.

- Thermal Shielding: Integration of heat sinks, thermal pads, or phase-change materials dissipates heat generated by high-power electronics. For environments with external heat sources, reflective coatings or double-wall construction provide added protection.

- Static and EMI/RFI Shielding: Multi-layer designs combine electrostatic discharge (ESD) protection, conductive gaskets, and metallic coatings to prevent signal degradation and safeguard against electrical surges. Applications range from medical equipment to wireless communication devices.

- Magnetic Shielding: Specialized materials and enclosure geometries deflect or absorb external magnetic fields, protecting sensitive analog or RF circuits.

- Dirt and Waterproofing: IP-rated seals, labyrinthine entryways, and corrosion-resistant materials ensure reliable operation in wet, dusty, or corrosive environments—critical for outdoor, marine, and industrial applications.

- Size, Shape, and Features: Custom enclosures can be tailored in size—from miniature cases for sensors to room-sized cabinets for industrial control rooms. Options include recessed areas for labels or keypads, cable management channels, locking mechanisms, removable panels, and modular designs for scalability.

- Branding and Aesthetics: Custom colors, finishes, screen printing, and engraving enhance product appearance and reinforce brand identity, particularly in consumer electronics and medical devices.

Considering a custom enclosure project? Ask yourself:

- What environmental hazards does my device face?

- What level of impact, thermal, or EMI protection is required?

- Will custom access points or mounting solutions streamline my installation?

- How can enclosure branding improve customer perception?

Consult with custom enclosure providers to discuss your application needs and design requirements.

Benefits of Electronic Enclosures

Utilizing high-quality electronic enclosures delivers a multitude of advantages that directly impact device reliability, user safety, and product lifecycle costs. Key benefits include:

- Environmental and Mechanical Protection: By isolating sensitive components from dust, moisture, chemicals, and physical impacts, enclosures extend device longevity and minimize downtime due to environmental damage or mishandling.

- Thermal Regulation: Enclosure features such as ventilation, heat sinks, and active cooling systems stabilize internal temperatures, reducing the risk of overheating and associated component failures.

- EMI/RFI Shielding: Effective shielding prevents signal loss, interference, and data corruption, ensuring regulatory compliance and uninterrupted device operation in noisy environments.

- Regulatory Compliance: Meeting IP or NEMA ratings, as well as industry-specific standards (UL, CE, RoHS), enables market access and instills customer confidence in product safety and reliability.

- Design Flexibility and Customization: Modular and custom enclosure designs allow for tailored solutions—incorporating cable management, mounting brackets, removable panels, and ergonomic features to fit unique device requirements.

- Aesthetic and Branding Advantages: Visually appealing, well-designed enclosures enhance user experience, reinforce brand reputation, and help products stand out in competitive markets.

- Serviceability and Upgradeability: Well-designed enclosures permit easy access for maintenance, repair, or component upgrades, reducing cost of ownership and maximizing product value.

Wondering how enclosures can benefit your specific application? Explore detailed use-case scenarios:

- Reducing downtime in industrial automation

- Ensuring patient safety in medical equipment

- Protecting data and power distribution in smart homes

- Enabling reliable operation of outdoor IoT sensors

For tailored solutions, connect with enclosure experts to discuss your project’s requirements.

Safety and Compliance Standards

Adherence to recognized safety and compliance standards is crucial in the selection and deployment of electronic enclosures. In the United States and worldwide, several organizations set performance and safety benchmarks for enclosure protection:

NEMA Types

The National Electrical Manufacturers Association (NEMA) defines enclosure types ranging from Type 1 (general indoor protection) to Type 13 (industrial and hazardous environments). Each NEMA rating specifies the enclosure’s suitability for indoor/outdoor use, resistance to environmental hazards, and capability to protect internal wiring and electronics. For instance, NEMA Type 4X enclosures are designed for outdoor and marine environments, offering protection from corrosion, water intrusion, and dust, while Type 12 is optimized for industrial settings requiring defense against dust, lint, and non-corrosive liquids.

For global applications, the IEC 60529 standard specifies Ingress Protection (IP) codes, such as IP65 or IP68, indicating an enclosure’s resistance to dust and water. These codes simplify cross-border compliance and ensure that enclosures meet international safety requirements.

When selecting an enclosure, always ask:

- Which NEMA or IP rating matches my environment?

- Does my industry require additional certifications (UL, CE, RoHS, ISO)?

- How do compliance standards impact warranty and insurance?

For more information, review our manufacturer listings or request regulatory guidance.

Finding the Right Manufacturer

Choosing the right electronic enclosure manufacturer is vital to project success—whether you need standard off-the-shelf products or fully custom solutions. Here’s a step-by-step approach to help you find the perfect fit:

- Identify Your Application Needs: Define environmental conditions, size constraints, required certifications, and any special features (e.g., EMI shielding, thermal management, custom branding).

- Review Manufacturer Capabilities: Explore manufacturers’ profiles, product catalogs, and case studies to assess their expertise in your industry and their ability to deliver tailored solutions.

- Engage Multiple Suppliers: Reach out to at least three or four manufacturers to discuss your requirements, request technical documentation, and compare pricing, lead times, and after-sales support.

- Evaluate Value-Added Services: Consider manufacturers offering design assistance, rapid prototyping, regulatory consulting, and lifecycle support to streamline your project.

- Check References and Certifications: Request references or customer testimonials, and verify compliance with applicable industry standards and quality certifications.

Ready to get started? Browse our curated list of electronic enclosure manufacturers or request a quote for your next project.

Frequently Asked Questions about Electronic Enclosures

- What is the difference between IP and NEMA ratings? IP ratings (Ingress Protection) are defined by IEC standards and indicate dust and water resistance, while NEMA ratings are US-based and also consider corrosion, oil, and other environmental factors.

- Can I customize enclosure size, shape, and features? Yes, most manufacturers offer custom design services, including unique shapes, access points, branding, and integrated cooling or mounting solutions.

- What materials should I choose for outdoor enclosures? Fiberglass, stainless steel, and polycarbonate are popular choices for outdoor and corrosive environments due to their durability, UV resistance, and weatherproof properties.

- How do I ensure my enclosure provides sufficient EMI/RFI protection? Specify enclosures with conductive materials, gaskets, and coatings, and consult with manufacturers about EMI/RFI shielding requirements for your application.

- Where can I find enclosure design guides or engineering support? Many leading enclosure manufacturers provide technical resources, design guides, and engineering consultation—visit their websites or contact them directly for assistance.

Still have questions? Speak with a specialist or request a product sample to evaluate enclosure solutions firsthand.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services