Instrument enclosures, enclosed in metal or plastic housing, safeguard electronic components. Due to their delicate wiring, these components often need to be shielded from dust, water, and unintentional touch. In addition, being contained helps to inhibit the entry of solid and liquid foreign items from reaching these units. Read More…

Since 1975, we have been doing precision sheet metal fabrication. Our expertise is in high production, high quality ISO 9000 Certified service. Dedicated manufacturing with on-time delivery. Electronic enclosures, chassis, frames, bracketry to extremely complex weldments and components.

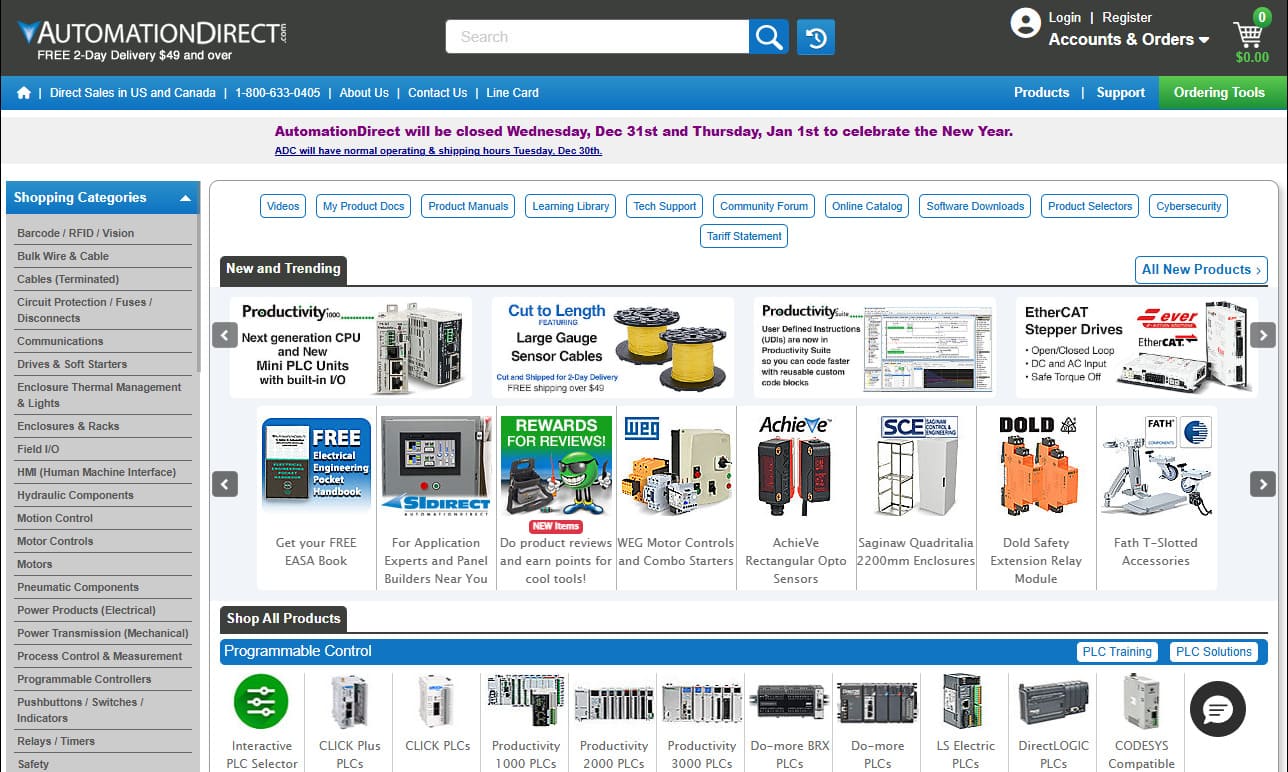

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

EMCOR® Enclosures is a modular enclosure manufacturer and makes related component items as well. Our electronic equipment racks and enclosures feature an extensive selection of rack heights, widths, depths, and styles that target your specific design requirements. A variety of external and internal accessories are available to complete your design. Modified or custom designs are also available....

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

Buckeye ShapeForm manufactures electronic enclosures and electrical enclosures that take your company to the next level! Different types include desktop, handheld and rackmount. We will help you with the entire process, from selection, design and customization to finishing.

More Instrument Enclosure Manufacturers

Instrument enclosures play a vital role in the protection, organization, and operation of sensitive electronic equipment across diverse industries. Whether you are searching for robust electronic instrument enclosures for industrial automation, customized housings for laboratory instruments, or durable outdoor enclosures for field-mounted devices, understanding the materials, designs, benefits, and applications of these protective solutions can significantly impact system performance and longevity. This in-depth guide explores the world of instrument enclosures—from key material choices and design variations to practical tips for selecting the right enclosure manufacturer for your project.

Common materials used for manufacturing instrument enclosures include aluminum, acrylonitrile butadiene styrene (ABS) plastic, stainless steel, and, for select models, polyester reinforced with fiberglass. These materials are carefully chosen to ensure that instrument enclosures provide robust protection for delicate, field-mounted electronic equipment, while maintaining stable internal temperatures and shielding sensitive components from environmental hazards such as moisture, dust, electromagnetic interference (EMI), and chemical exposure.

Fiberglass instrument enclosures offer strength comparable to stainless steel, making them suitable for harsh industrial settings. In addition to their high tensile strength, fiberglass enclosures boast several advantages, such as lightweight construction, inherent resistance to corrosion, superior chemical durability, and excellent flame resistance. These properties make fiberglass a preferred material for applications where both strength and chemical inertness are essential.

On the other hand, many modern instrument enclosures leverage the lightweight and malleable nature of aluminum. By using a combination of diecast, extruded, and fabricated aluminum elements, manufacturers can produce enclosures with appealing visual designs and easy assembly. These aluminum enclosures are ideal for housing delicate electronics—offering both structural integrity and a refined appearance suitable for professional and commercial environments.

Instrument enclosures often feature separate anodized front and rear panels, which allow for the quick mounting of controllers, displays, and connectors. This modular design makes it easier to integrate new technologies or upgrade existing systems. Customizable instrument enclosures can also be tailored to fit printed circuit boards (PCBs), power supplies, sensors, and a variety of electronic components, supporting diverse use cases in health and wellness, industrial automation, medical diagnostics, laboratory testing, and environmental monitoring.

Designs of Instrument Enclosures

The design of an instrument enclosure is crucial to its effectiveness in safeguarding electronic instruments. Various enclosure designs are available to accommodate the unique requirements of different devices and installation environments. When evaluating enclosure solutions, consider the following common design categories:

- Portable and Handheld Enclosures: These are specifically engineered for small, mobile devices that require long-lasting protection and shock absorption. Portable enclosures often include ergonomic features, such as textured grips, slide-on covers, or LCD screen cutouts. When searching for handheld instrument enclosures, ask: What features enhance portability and operator comfort?

- Desktop Instrument Enclosures: Ideal for benchtop equipment, these enclosures shield devices from accidental spills, dust, and unintended contact. Their box-like, durable construction offers reasonable size and weight for easy handling. Many desktop enclosures incorporate vents, handles, locking mechanisms, and membrane keyboards for enhanced usability.

- Wall-Mounted Instrument Enclosures: Designed to be mounted near the equipment they regulate, wall enclosures protect contents from dust, dirt, splashing water, and unauthorized access. Commonly installed on DIN rails, these enclosures slide into position for straightforward installation and maintenance. Consider wall-mounted enclosures with transparent lids or access panels for real-time monitoring and easy component access.

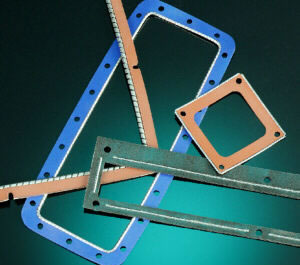

- Outdoor and Industrial Enclosures: Built to withstand extreme temperatures, UV exposure, moisture, and corrosive chemicals, these rugged housings may include watertight gaskets, recessed regions for labels or keypads, and special coatings for EMI/RFI protection. If you need weatherproof or waterproof instrument enclosures, look for models with high IP or NEMA ratings.

Other advanced enclosure features include transparent lids or covers, cylinder catches, lock covers, thermometers, drains, air dryers, and special coatings to shield internal components from electrostatic discharge (ESD), electromagnetic interference (EMI), and radio frequency interference (RFI). For metal enclosures, aluminum extrusions or cold-rolled sheet metal offer a seamless, durable structure, while plastics, fiberglass, and composite materials increase resistance to corrosion and reduce overall weight.

Key Benefits of Instrument Enclosures

Choosing the right instrument enclosure brings a range of functional and operational advantages. Below are some of the top reasons why engineers, laboratory managers, and system integrators invest in high-quality enclosure solutions for their instrumentation:

- Personnel Safety: Laboratory and industrial environments often pose numerous health and safety risks, especially during pharmaceutical testing, sample preparation, and powder-handling operations. By enclosing hazardous processes, instrument enclosures help protect workers from exposure to airborne pollutants and hazardous substances. Modern enclosure systems offer a secure handling and testing environment that meets strict safety standards for pharmaceutical, biotech, and chemical processing industries.

- Equipment Protection: Enclosures safeguard sensitive electronic devices from mechanical damage, moisture, dust ingress, static discharge, and chemical exposure. For desktop instruments, robust housings shield components from spills and unintended contact, while wall-mounted enclosures prevent dust, dirt, lint, and water from reaching critical control systems.

- Process Reliability: LEV (local exhaust ventilation) systems and specialized instrument enclosures ensure effective containment with minimal energy consumption. Modular enclosure architectures allow laboratories and manufacturing environments to adapt quickly—enabling future upgrades, expansion, and easy access for maintenance.

- Regulatory Compliance: Many industries, including medical device manufacturing and pharmaceuticals, must adhere to strict regulatory requirements regarding equipment protection, contamination control, and electrical safety. Certified instrument enclosures help meet these requirements and facilitate easier compliance during audits.

- Enhanced Aesthetics and Branding: Customizable enclosures can be designed to match corporate branding, color schemes, and ergonomic requirements—contributing to a professional appearance and improved user experience.

- Environmental Control: For temperature-sensitive electronics, enclosures with integrated thermal management features (such as fans, vents, heat sinks, or insulation) maintain stable internal conditions, extending the lifespan of electronic components and reducing the risk of thermal failure.

- EMI/RFI Shielding: Electromagnetic and radio frequency interference can disrupt sensitive measurement and control devices. Enclosures featuring EMI/RFI shielding minimize signal degradation, ensuring reliable data transmission and accurate readings.

Applications of Instrument Enclosures

Instrument enclosures are indispensable across a wide range of industries and use cases. Whether you are seeking custom electronic enclosures for laboratory automation or durable housings for field-deployed sensors, understanding the diverse applications can help you specify the right solution for your needs. Common applications include:

- Laboratory Instruments: Used to house analyzers, spectrometers, balances, and sample preparation devices, laboratory instrument enclosures deliver reliable protection against contamination, accidental spills, and unauthorized tampering. High-quality enclosures also facilitate cable management and modular expansion for rapidly evolving research environments.

- Medical Devices: From diagnostic analyzers to patient monitoring systems and point-of-care instruments, medical device enclosures must meet stringent hygiene, safety, and performance standards. Sealed and easy-to-clean enclosures help prevent biohazard contamination and protect embedded electronics.

- Industrial Automation and Process Control: Instrument enclosures are essential for protecting PLCs, HMIs, sensors, control panels, and other automation components in manufacturing plants, refineries, and utilities. Ruggedized housings withstand vibration, chemical exposure, and EMI, supporting uninterrupted operations.

- Environmental Monitoring: Weatherproof enclosures protect air quality sensors, water monitoring probes, meteorological equipment, and remote data loggers from harsh outdoor conditions. Enclosures with high IP/NEMA ratings ensure reliable performance in rain, snow, or extreme temperatures.

- Test and Measurement Equipment: Portable and benchtop enclosures are used for oscilloscopes, signal generators, power supplies, and field calibration tools. For mobile technicians, handheld enclosures with ruggedized construction and protective bumpers enhance durability during on-site testing.

- Data Acquisition and IoT Devices: As businesses increasingly depend on interconnected devices to drive productivity and decision-making, secure instrument enclosures protect internal electronics, batteries, and communication modules from both physical tampering and cyber threats.

- Custom Applications: From audio-visual control boxes and scientific research instruments to bespoke sensor housings for aerospace and defense, custom enclosure solutions are engineered to meet the most demanding requirements. Ask yourself: Does your application require a custom shape, cutouts, or branding elements?

Decision Factors When Choosing Instrument Enclosures

Selecting the right instrument enclosure for your application involves careful evaluation of several key factors. Here are some points to consider when comparing enclosure options:

- Material Selection: Consider the environmental conditions (humidity, temperature, chemical exposure) and the required level of protection (IP/NEMA rating). Aluminum, stainless steel, ABS plastic, and fiberglass each offer distinct advantages depending on your use case.

- Size and Compatibility: Ensure the enclosure dimensions accommodate all internal electronic components, PCBs, connectors, and cable routing requirements.

- Thermal Management: For electronics prone to overheating, look for enclosures with integrated cooling solutions, such as vents, fans, or heat sinks.

- EMI/RFI Shielding: If electromagnetic interference is a concern, select enclosures with appropriate shielding materials or coatings.

- Ease of Installation and Maintenance: Modular designs, hinged doors, removable panels, and tool-less entry features simplify installation, upgrades, and routine maintenance.

- Customization Options: Do you require custom cutouts, silk-screened labels, or special color finishes? Many enclosure manufacturers offer tailored solutions for unique requirements.

- Compliance and Certification: Confirm that the enclosure meets relevant industry standards (such as UL, IEC, RoHS, or FDA) for electrical safety, fire resistance, and environmental protection.

- Cost and Lead Time: Balancing the initial investment with the total cost of ownership, consider factors such as warranty, availability, and manufacturer reputation.

Not sure which enclosure best suits your project? Ask these questions: What is the primary function of the enclosure? Will it be exposed to harsh environments? Does it require frequent access for maintenance or upgrades? How important are aesthetics and branding in your industry?

How to Select the Right Instrument Enclosure Manufacturer

Partnering with a reliable instrument enclosure manufacturer is critical to ensuring product quality, timely delivery, and long-term support. Here are some practical tips to streamline your procurement process and maximize value:

- Evaluate Manufacturer Expertise: Use our directory of instrument enclosure manufacturers to compare companies, explore their experience, and review their areas of specialization. Leading manufacturers often offer in-house design, prototyping, and rapid customization services.

- Review Business Profiles: Each manufacturer has a business profile page that highlights capabilities, certifications, and case studies. Leverage these resources to assess whether a potential partner can meet your technical and regulatory requirements.

- Request Quotes and Samples: Use integrated contact forms to request additional information, seek technical advice, or ask for a detailed quote. For custom projects, request prototypes or product samples to verify fit and performance.

- Utilize the Website Previewer: Quickly learn what each business specializes in by using our proprietary website preview tool, allowing you to efficiently shortlist vendors based on your needs.

- Simplify RFQ Submissions: Use our streamlined RFQ (Request for Quote) form to contact multiple instrument enclosure companies simultaneously, making it easier to compare pricing, lead times, and service offerings.

- Ask About After-Sales Support: Inquire about warranty terms, technical support, and spare parts availability to ensure a smooth product lifecycle and minimize downtime.

Are you ready to take the next step? Contact leading instrument enclosure manufacturers now to discuss your project requirements, request a custom quote, or schedule a design consultation.

Frequently Asked Questions (FAQs) About Instrument Enclosures

- What are the main types of instrument enclosures? Instrument enclosures come in portable, desktop, wall-mounted, rack-mounted, and outdoor/industrial designs, each tailored for specific environments and device types.

- What materials offer the best protection for sensitive electronics? Aluminum and stainless steel provide excellent protection against impact and EMI. Fiberglass and ABS plastic offer lightweight, corrosion-resistant alternatives ideal for chemical or moisture-prone environments.

- How do I choose the right IP or NEMA rating? Assess the level of protection required against dust, water, and accidental contact. Higher IP/NEMA ratings indicate better ingress protection for harsh or outdoor environments.

- Can instrument enclosures be customized? Yes. Leading manufacturers offer custom cutouts, color options, branding, mounting solutions, and even integrated thermal management systems.

- Do enclosures affect signal transmission? With proper EMI/RFI shielding and grounding, high-quality enclosures provide protection without compromising data integrity or signal reliability.

- Where can I find reputable instrument enclosure suppliers? Use our comprehensive directory of instrument enclosure manufacturers and suppliers for easy comparison and direct contact options.

Conclusion: Maximizing Performance with the Right Instrument Enclosure

In today’s technology-driven landscape, instrument enclosures are more than just protective shells—they are a critical element in ensuring the reliability, safety, and efficiency of electronic systems. From laboratory research and medical diagnostics to industrial automation and IoT deployments, the right enclosure solution safeguards valuable assets, simplifies maintenance, and supports regulatory compliance.

By understanding material options, design features, use cases, and decision factors, you can confidently specify the ideal instrument enclosure for your project. Ready to find the best enclosure solution? Browse our directory of instrument enclosure manufacturers to compare products, request customizations, and connect with experts who can help you achieve your operational goals.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services