Metal enclosures are meticulously designed and produced metal cases and covers that are made to fit a specific application. The components are typically utilized to encircle and safeguard crucial components. They are frequently employed when pollutants or moisture are a problem, such as protecting expensive hardware from the weather. Instead, some metal enclosures serve the opposite purpose: keeping a system’s internal parts contained so they don’t seep into the surroundings or nearby compartments. Read More…

Maysteel provides complex sheet metal fabrication with a focus on design for manufacturing. Founded in 1936, we combine our extensive engineering experience and market knowledge with an expanding supply chain footprint, allowing us to fabricate products that others can’t. We design, engineer and manufacture custom OEM sheet metal enclosures, kiosks, cabinets and racks. We have locations in the...

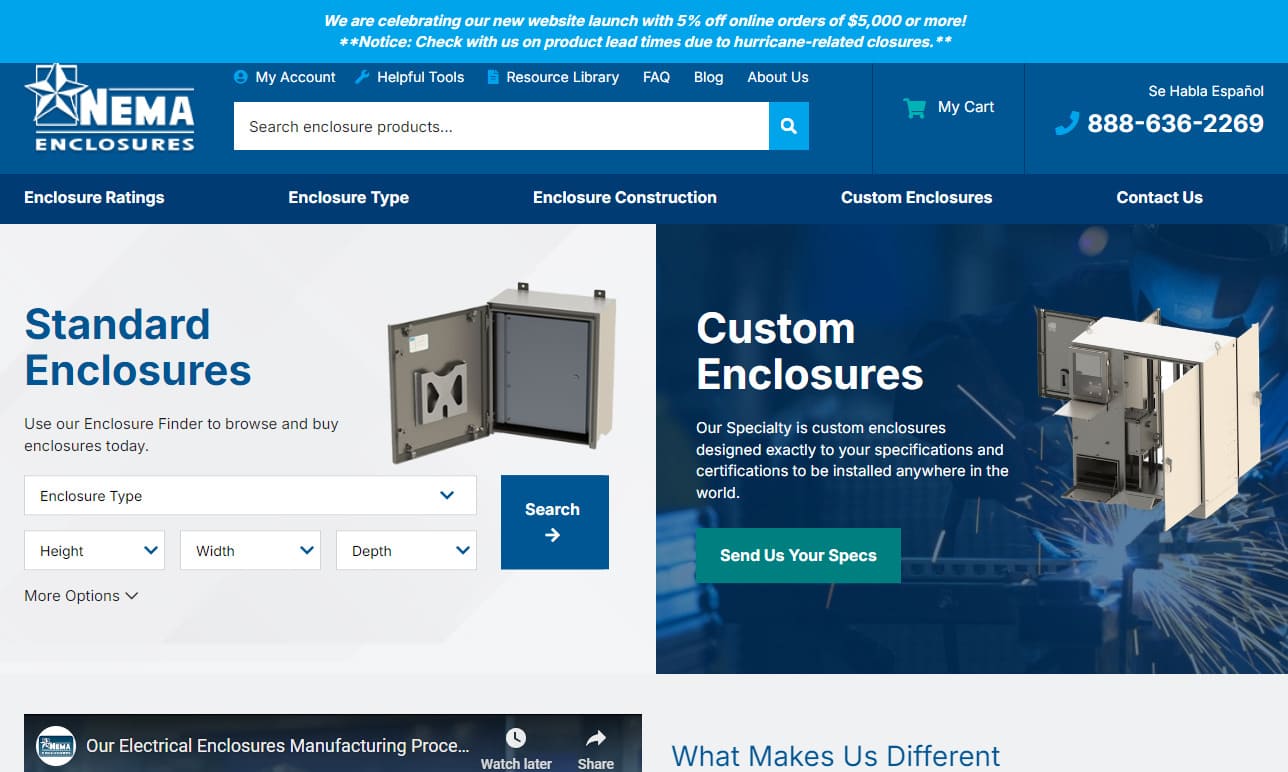

At Nema Enclosures Mfg. Corp., we are dedicated to crafting high-quality electronic enclosures tailored to meet the diverse needs of our clients. Our expertise lies in designing and manufacturing robust and reliable enclosures that safeguard sensitive electronic equipment from environmental factors such as dust, moisture, and extreme temperatures. Our extensive range of electronic enclosures...

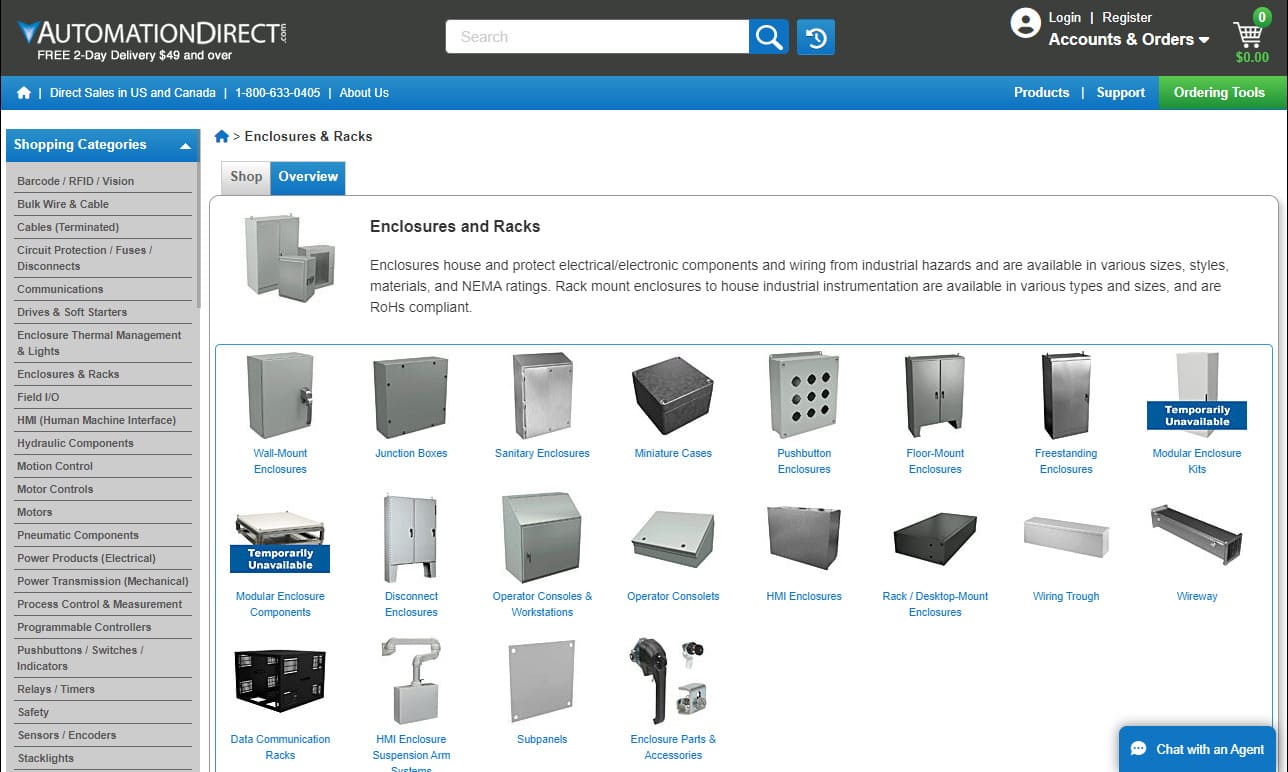

AutomationDirect.com takes pride in being a trusted partner for businesses seeking reliable electronic enclosure solutions. Our team is dedicated to providing exceptional customer service and technical support to ensure that our customers find the perfect products to meet their needs.

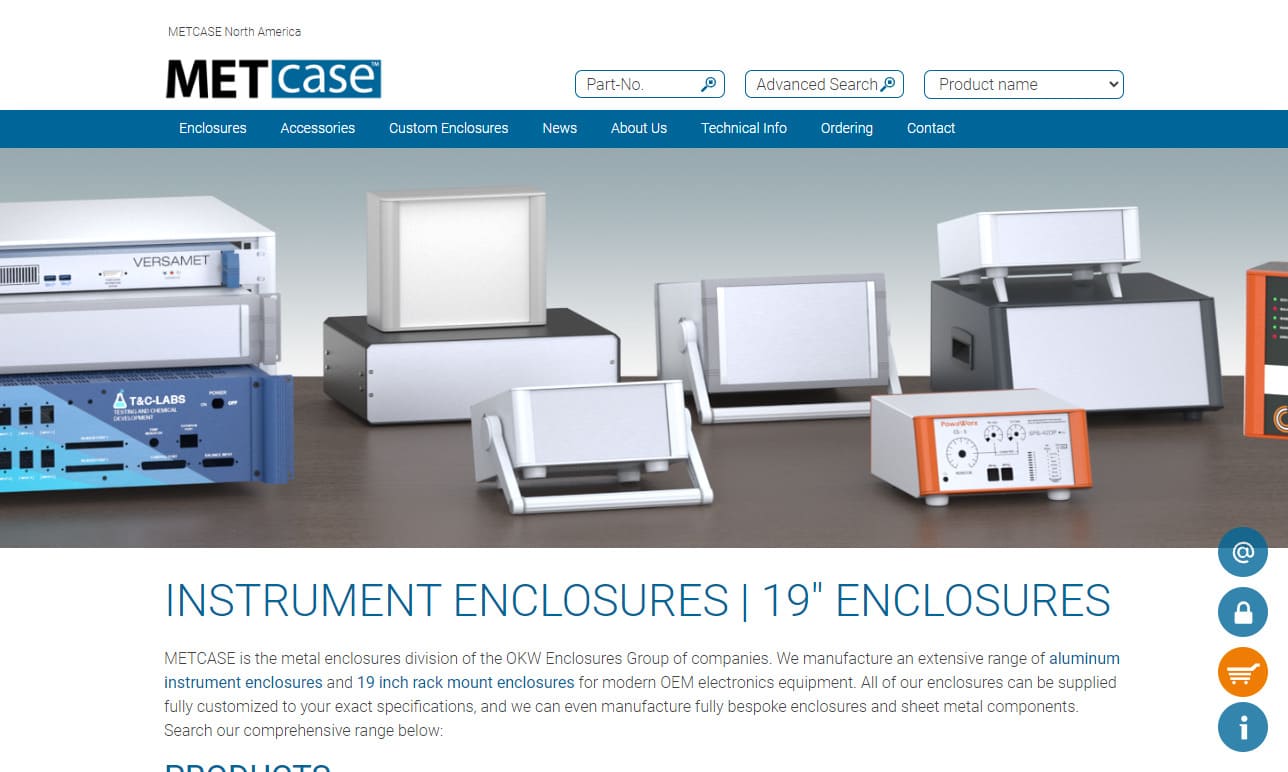

At METCASE, we specialize in the design and manufacturing of high-quality electronic enclosures tailored to meet the diverse needs of our clients. Our extensive range of products includes standard enclosures, custom designs, and accessories that cater to various industries and applications. We take pride in our ability to deliver solutions that combine functionality with aesthetic appeal,...

At Accurate Metal Fabricating, we specialize in crafting precision-engineered electronic enclosures that meet the unique demands of modern industries. With a relentless commitment to quality, we pride ourselves on providing cutting-edge enclosures that safeguard electronic components with unparalleled accuracy. At the heart of our success is a passion for innovation, driving us to create...

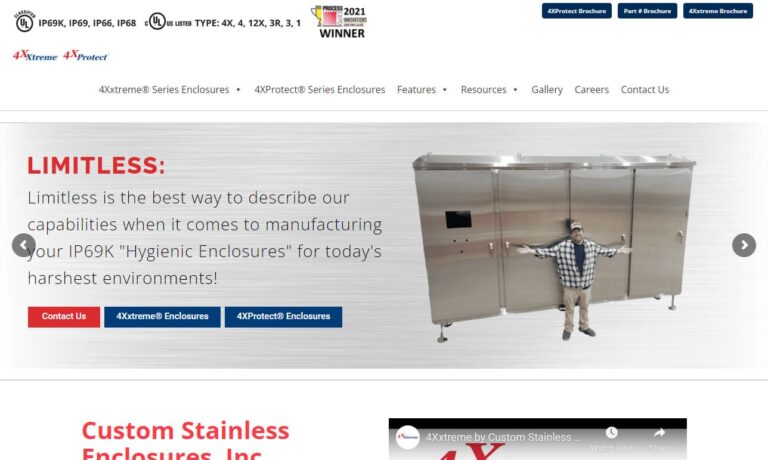

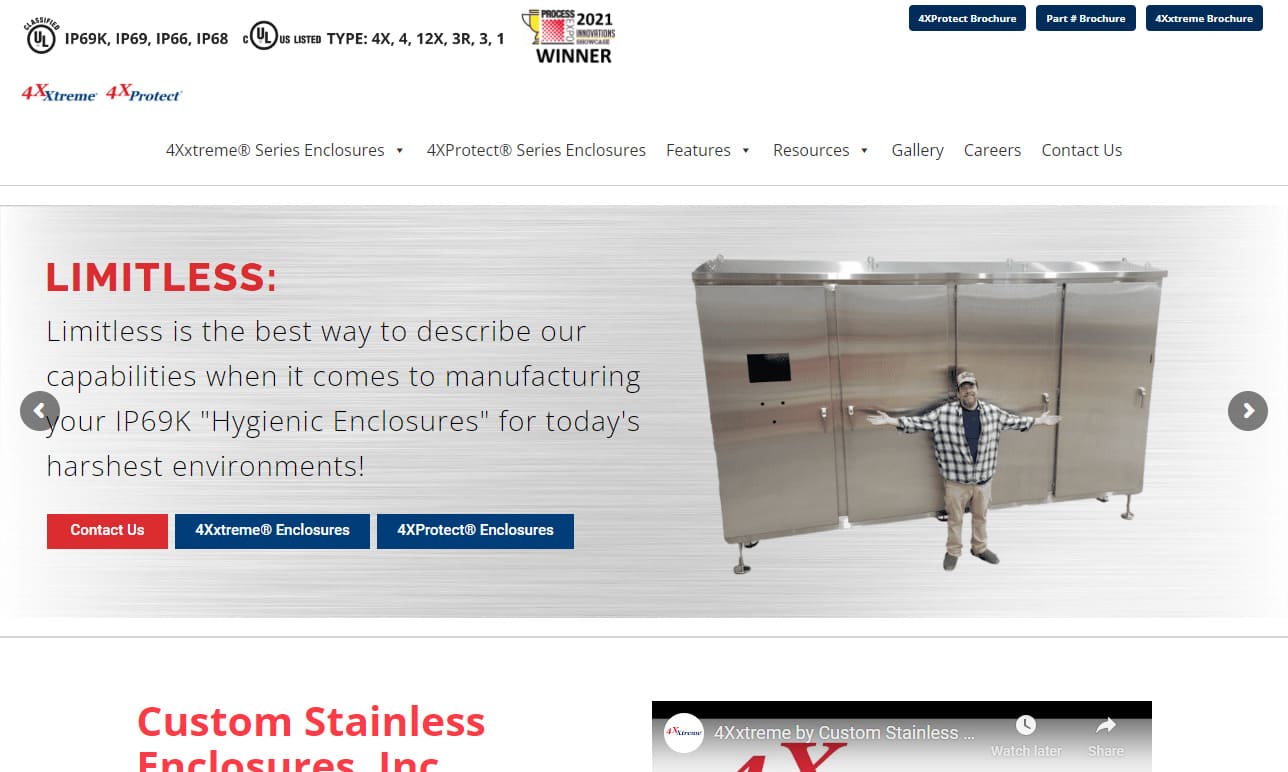

At Custom Stainless Enclosures, Inc., we specialize in crafting high-quality electronic enclosures tailored to meet the diverse needs of our clients. Our commitment to excellence begins with the meticulous design of each enclosure, ensuring that every product is not only durable but also precisely engineered to accommodate the specific requirements of various electronic components. We pride...

More Metal Enclosure Manufacturers

Containers, boxes, and other manufactured shapes are considered metal enclosures and are used to hold, store, and enclose various objects. Metal enclosures include numerous electrical cabinets such as stainless steel and carbon steel enclosures. Metal casings are straightforward in comparison to other manufactured metal goods. However, metal cabinets are one of the most significant and popular metal enclosures.

Manufacturing Processes of Metal Enclosures

Metal Stamping

Metal stamping techniques are widely used for this kind of component. These processes shape plain sheet metal into simple or complex shapes.

Detailed Stamping

This method is especially useful for enclosures that need to be taller than wide, like those that protect cylinder tanks. In various applications, deep-drawn stamping creates smooth, durable casings with exceptional precision. Additionally, this kind of manufacturing can decrease the number of connected surfaces or material seams on a component, which lowers the possibility of a mechanical problem or the need for material reinforcement at weaker seams.

Progressive Die Casting

Progressive die casting enables continuous production with dramatic shaping, and is useful for enclosures with ever-more complex configurations. In addition, material can be progressively changed utilizing the progressive die casting process to reduce material fatigue and increase the strength of the completed component.

Finishing Techniques

Finishing techniques are also beneficial and popular for the fabrication of these components. Regardless of the material or manufacturing process, additional treatment is typically necessary to stiffen and harden the case of metal enclosures. With finishing processes like hardening, annealing, or other heat treatment, metal enclosures can be adequately equipped for the worst situations, including acidic or extremely cold temperatures.

Applications

Metal shapes and enclosures have industrial uses. Any company that uses delicate or expensive hardware, whether it be cells, power components, or drilling equipment, can benefit from metal enclosures. The proper metal enclosure shields these systems from fluids, pollutants, and debris, maintaining their performance and reducing downtime. Industrial enclosures do the same thing by preventing dust accumulation, which over time can lower the quality of the product and interfere with efficient equipment operation.

The greatest method to reduce these hazards and keep systems optimally functioning is with safe, properly-fitted metal enclosures. For example, a metal electrical enclosure, like a fuse box, a crucial piece of electrical regulatory equipment that controls output power and prevents electrical fires, is present in every facility that uses electricity.

Additionally necessary for the efficient operation of the electrical parts in homes and companies are outdoor electrical meters. Fuse enclosures and electrical meters are both encased in metal casings that shield them from accidental impact and exposure to pollutants like dust and dirt. Metal enclosures offer this protection in a variety of contexts.

Advantages of Metal Enclosures

Metal enclosures provide many important advantages. In addition to corrosion resistance, these include the capacity to tolerate extreme temperature conditions, sunlight, and all forms of precipitation. In addition, metal enclosures are made stronger and more resistant to shock and vibration thanks to the mixture of seamless stamping methods and annealing treatments. These advantages make metal enclosures suitable for the most demanding applications, such as emergency and military uses inside and outside.

For example, technical directors of theaters and concert venues frequently favor steel enclosures with glass doors. Valuable video and audio equipment must frequently be shielded from contamination and collisions. It also occasionally makes noises that aren't expected and can be distracting during presentations or performances. These noises are contained by metal cages with glass doors, allowing technical employees to monitor their tools.

Considerations When Buying Metal Enclosures

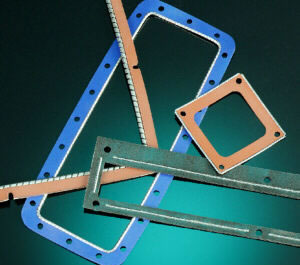

Organizations like the National Electrical Manufacturers Association (NEMA) rank a variety of metal enclosures. Using these evaluations, experts can quickly and easily assess the enclosures' functional and protective qualities before making a purchase. Because there are so many different types of critical assets housed in metal enclosures, these organizations are vital. For instance, the problem of EMI (electromagnetic interference) has become a significant concern due to the growing use of cutting-edge technology and the speedy advancement of modern electronic devices.

Selecting a container that can offer EMI protection when operating equipment in EMI-containing conditions is crucial as EMI becomes a more prevalent issue. High-temperature environments and electronic circuit requirements must be considered while choosing cabinets for fragile electrical components. These factors are yet other important aspects that have a significant impact on the choice of material for electronic enclosures.

Plastics can be used to make enclosures for electronic systems that don't need a lot of thermal transfer because they are good insulators. Metal enclosures, on the other hand, are more appropriate for circuit systems with high current and voltage demands, which may reflect in extremely high energy density and heat transmission.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services